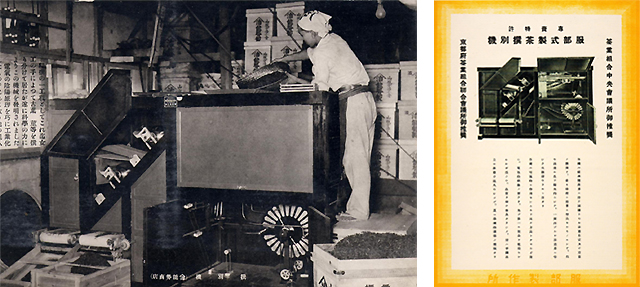

Until the 1930’s, in Japanese tea factories, women called “Sorting girls” were removing stems from tea leaves manually by hand to make processed tea.

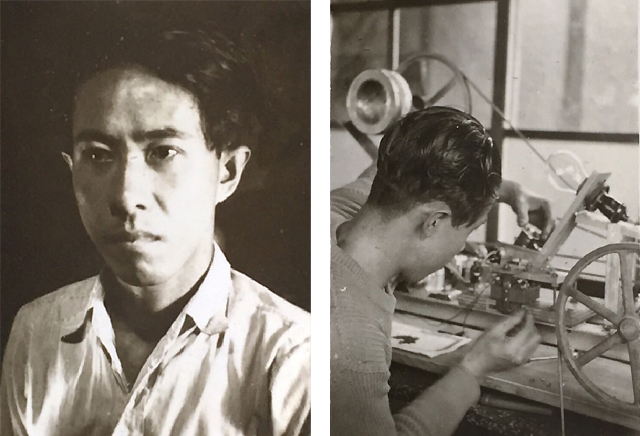

18 years old Zen-ichi Hattori was helping his family business of tea manufacturing and considering the way to save labor in stalk removing process. He eventually found the phenomenon of tea leaves to be charged positive and stalks to be charged negative. He invented the machine to separate stalks and leaves by electrostatic phenomenon.

After years of trial and error, the first electrostatic stalk extractor (Type A) was invented and patented. Hattori Seisakusho company was established at the same time. 100 units of Type A were manufactured.

In 1956, Zen-ichi Hattori received the Medal of Honor with the Purple Ribbon for his invention of the electrostatic tea stalk extractor.

Electrostatic stalk extractor has been developed to have semiconductor diode to convert AC to DC and iron frame and panel. In 1960, two stage electrostatic sorter Type DW was released.

Electrostatic stalk extractor could reduce stalk contamination from 50% to 15% and it could reduce labor, but balance stalk has to be removed manually. To overcome the weakness of electrostatic stalk extractor, the machine to remove stalk by color was developed in 1964. This model H30 is the first color sorter for tea in the world.

Type : H30

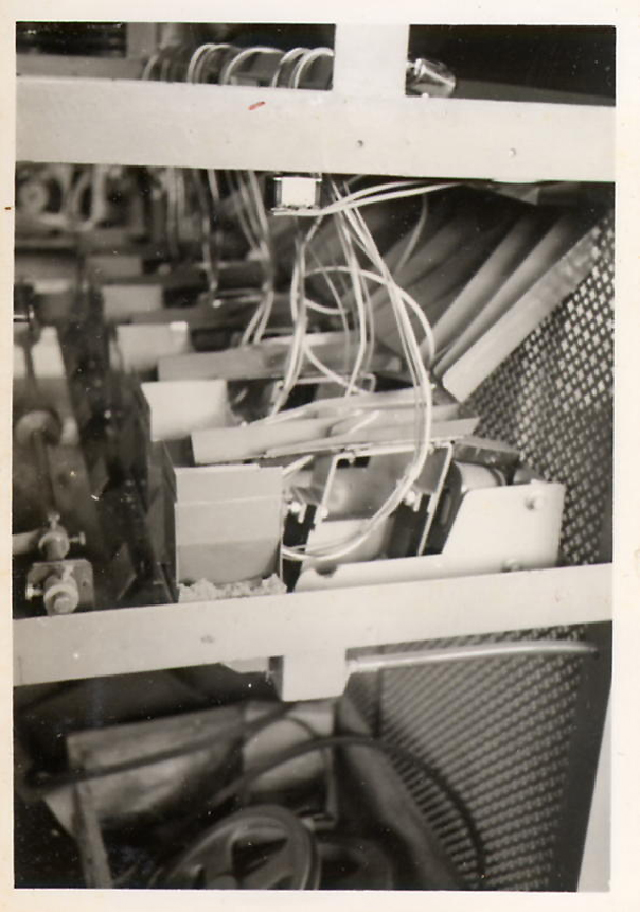

Stalk is removed on electromagnetic vibrator. Vibrator has 2 grooves.

Material tea is fed on one groove and when stalk is detected, ejector blows on

the side of tea and stalk is moved to the next groove and carried to different

outlet.

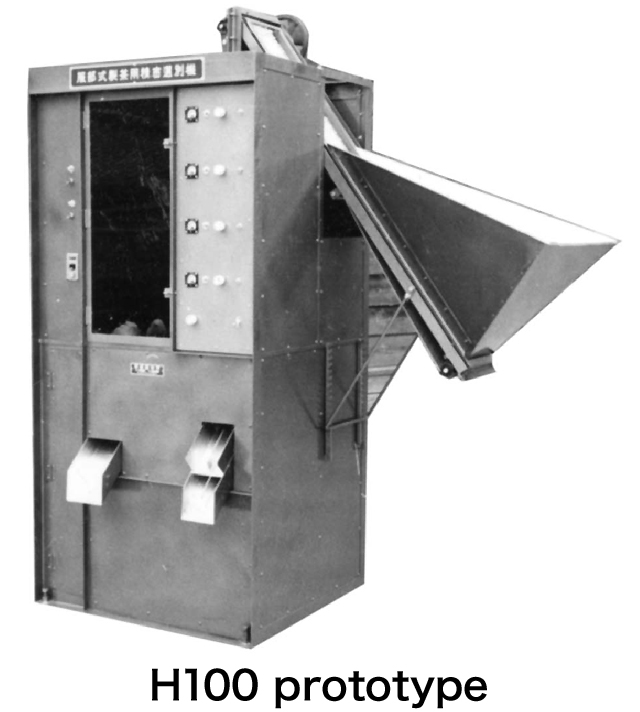

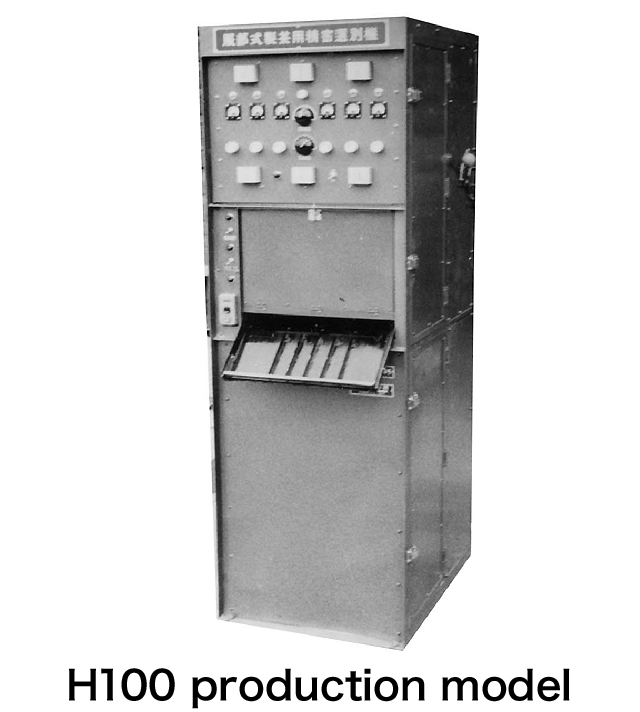

To improve throughput capacity of H30 type color sorter, the mechanism to

increase feeding speed was tried in many prototypes. In H100 prototype (in 1967),

tea is accelerated and arranged in one line by rotating disc. Finally, the mechanism

of tea feeding is established in Type H100 (in 1967). Tea falls on V shape chute

and fed to inspection area in vertical manner. This mechanism has been adopted

as a standard feeding mechanism of Tea Color Sorter for over 30 years.

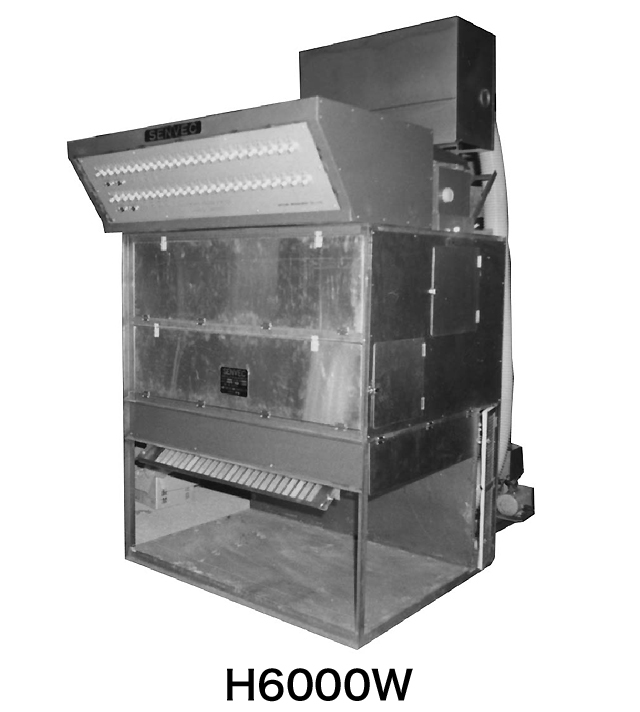

In 1978, two stage type color sorter H6000W is released. Even high stalk contamination

tea can be cleaned in one pass by two stage sorting.

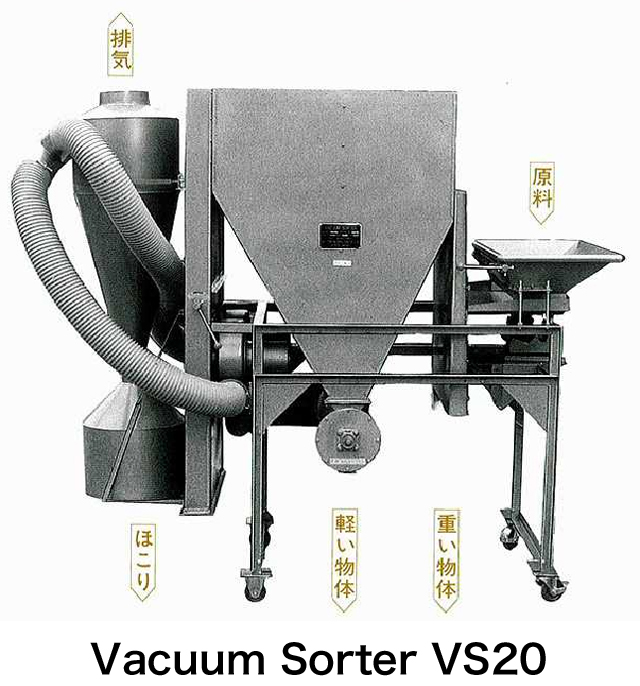

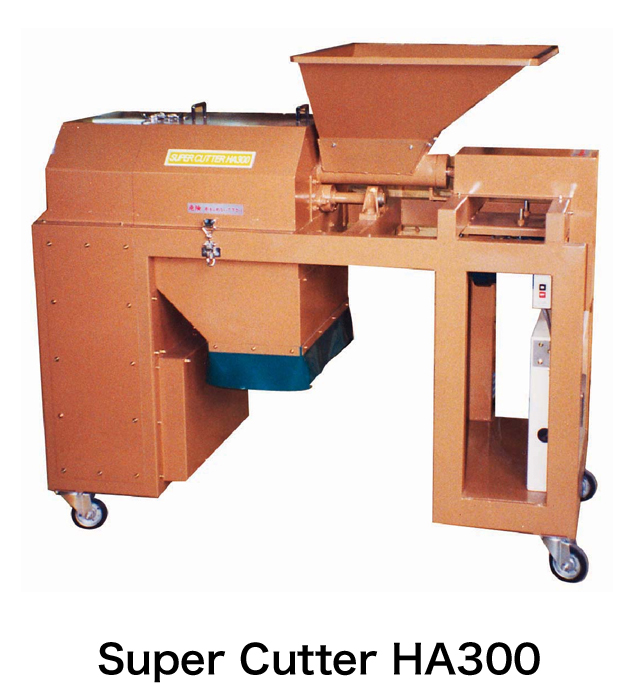

In 1977, the Vacuum Sorter VS series, which removes powder and fiber in Tea refining process, was released. In 1982, the super cutter HA series, which cuts Sencha Leaf in even narrow and long shape, was released.

In 1981, the N series, which has low noise and high sensitivity sensor amplifiers,

was released. In 1983, the C series was released. This model integrated sensor

amplifier and ejector driver in one unit and simplified assembling and servicing.

Over 4000 unit of C series are sold in Japan and export to India and Sri Lanka

also started in 1984.

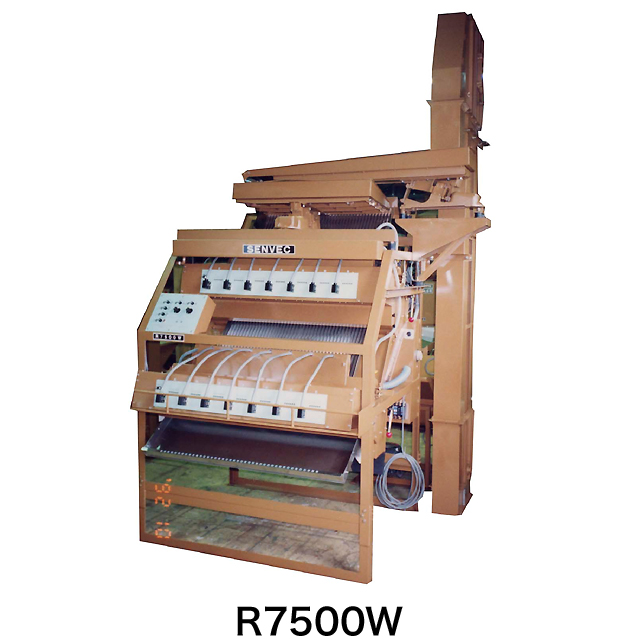

In 1986, the R series was released. This model was designed for black tea and

equipped with “Color sensor” instead of monochromatic sensor. Over 500units are

exported to Sri Lanka, India, Indonesia and Vietnam

Monochromatic sensor type Beans Color Sorter NCS series was released in 1990, Color sensor type Beans Color Sorter NCO series was released in 1992 and Rice Color Sorter KC series was released in 1994. Those models created new market for Color Sorter.

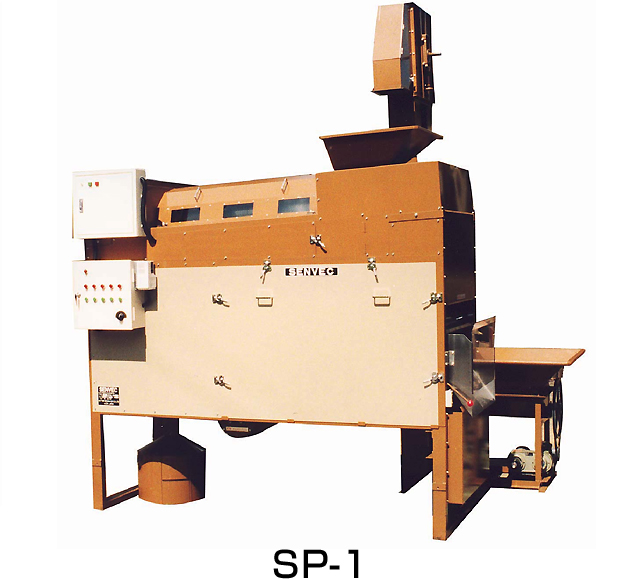

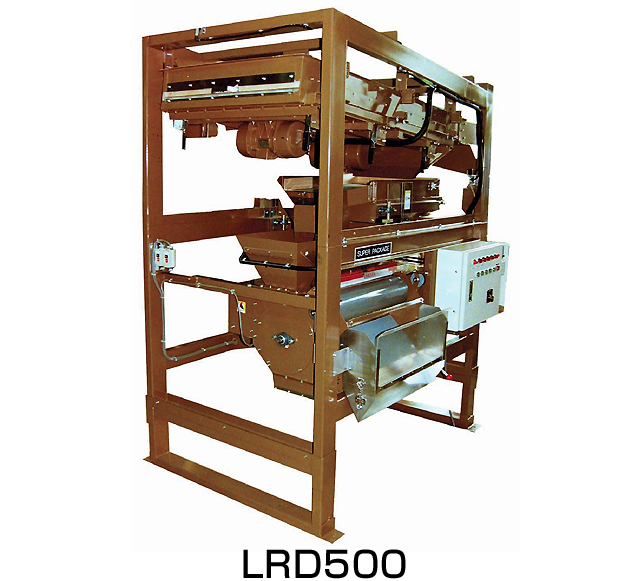

Microwave Drier MG series was released in 1992 for re-drying process of Sencha. In 1999, integrated Sencha refining machine SP(Super Package) series was released. Cutter, Sifter, Vacuum Sorter and Electrostatic stalk remover are integrated in one package for automating Sencha refining process. Simplified packager LRD series was released at the same time.

In 1999, new CCD camera type Rice Color Sorter S2000 series was released.

By adapting CCD camera, minimum detecting size has become 0.3mm and throughput

has become double, comparing with the same size photo sensor type machine. CCD

camera was also applied to Belt Conveyer type Color Sorter and BS2000 series

was released in 2002.

In 2003, CCD camera type Tea Color Sorter GTS series was

released. Technical trend of Color Sorter has moved to CCD camera sensing.

In 2001, Powder Color Sorter PS2000 series was released.

In 2002, Color CCD camera type Color Sorter was developed. Chute type CS2000,

Belt Conveyer type BCS2000 and Tea and Herb sorter CS2000-W series was released.

By adapting Color CCD camera, color sorting application has increased and market

has expanded.

For the demand of low cost high capacity Black Tea Color Sorter in Sri Lanka and India, Belt Conveyer type Tea Color Sorter BTR series was released in 2003. To minimize maintenance cost, flat chute type Black Tea Color Sorter FTR series was released in 2006.

In 2006,FMG series foreign material remover for Green Tea was released.

In the same year of 2006, DV series Color Sorter, which was designed for foreign material removing from food by Color camera and Infra-Red camera, was developed. Chute type DVS, Belt Conveyer type DVBS and two stage chute type DVR series was released.

To support a variety of needs of the customer, 4 side inspection Color Sorter DVX was released in 2013、Powder Color Sorter DVPS was released in 2013、DVBS-WET, the Color Sorter for wet food was released in 2015.

After 10 years of DV series, UD series was released in 2016. Automatic Programming function enabled operator’s self-programming and shape recognition camera can be used with color camera in Conveyer type model.

- Product

- Sorters for Food, Industrial and Medical processing

- Color Sorters for Tea

- Tea Processing Machines